Effect of Cryogenic Treatment on Residual Stress and Dimensional Stability of 2A14 Aluminium Alloy after Solid Solution and Aging

-

摘要:

对2A14铝合金依次进行(380±5)℃×120 min退火、498 ℃×2 h固溶、160 ℃×6 h时效以及不同温度(−70,−90,−110,−130 ℃)保温6 h深冷+160 ℃×3 h时效处理,研究了深冷处理对试样内部残余应力、物相组成、微观结构、尺寸稳定性和力学性能的影响。结果表明:不同热处理后试样中心纵截面残余应力均呈内拉外压形式,深冷处理对残余拉应力的释放效果和对应力分布均匀化效果随深冷温度降低均先增后减,−90 ℃下深冷处理应力释放和均匀化效果最好;−130~90 ℃深冷处理可以细化晶粒、增加析出相数量、减小析出相尺寸、降低位错密度、提高析出相和位错分布弥散性;−130 ℃~70 ℃深冷处理可以提高2A14铝合金的尺寸稳定性、抗拉强度和屈服强度,但会降低断后伸长率。

Abstract:2A14 aluminum alloy was treated by annealing of (380±5) ℃×120 min, solid solution of 498 ℃×2 h, aging of 160 ℃×6 h, cryogenic under different temperatures (−70, −90, −110, −130 ℃) for 6 h and aging of 160 ℃×3 h in sequence. The effect of cryogenic treatment on residual stress, phase composition, microstructure, dimensional stability and mechanical properties of the samples was investigated. The results show that the residual stress on the longitudinal section at center of the samples after different heat treatments was in the form of internal tension and external pressure. The release and stress distribution homogenization effects of cryogenic treatment increased first and then decreased with the decrease of temperature. The stress release and homogenization effects by cryogenic treatment at −90 ℃ were the best. The cryogenic at −130—−90 ℃ could refine the grains, increase the number of precipitates, reduce the size of precipitates and the dislocation density, and increase the dispersion of precipitates and dislocations. Cryogenic treatment at −130—−70 ℃ could improve dimensional stability, tensile strength and yield strength of 2A14 aluminium alloy, but reduced the percentage elongation after fracture.

-

0. 引言

2A14铝合金具有良好的综合力学性能、焊接性能、可切削性和低密度,是飞机的主要结构材料[1-4],常制作成大型薄壁构件。然而,由于这种大型薄壁构件刚性弱且材料去除率高,极易在制造过程中发生变形并影响其尺寸精度[5]。内部残余应力的存在是引起加工变形和尺寸精度变化的重要因素,因此,调控内部残余应力对于改善薄壁构件尺寸稳定性具有重要意义[6]。

在消解残余应力时,常采用机械拉伸[7]、振动时效[8]、热处理时效[9]、自然时效[10]、超声调控[11]和深冷处理[12-14]等方法。其中,深冷处理因具有操作简便、释放应力效果好以及不受零件形状尺寸限制等特点,广泛用于铝合金内部残余应力调控领域[15-17]。此外,深冷处理还可以改善金属材料的力学性能、耐磨性能和耐腐蚀性能等[18-23]。WENG等[13]采用盲孔法研究了深冷处理对7050铝合金残余应力和尺寸稳定性的影响,结果表明深冷处理能显著降低残余应力并提高尺寸稳定性。SHANG等[14]采用轮廓法研究了深冷处理对抗氢钢薄壁内部残余应力的影响,结果表明深冷处理后内部残余应力分布特征不变,大小降低了57%~63%。NIU等[21]研究发现,深冷处理可以使2A12铝合金晶粒细化,减少析出相的聚集现象,并使残余应力降低了93%。ZHOU等[22]研究发现,深冷处理过程中AlSi10Mg合金因铝基体和共晶硅体积收缩不一致而产生塑性变形,使得合金中的残余压应力被保留,并抵消了残余拉应力,同时合金的力学性能得到保持。

为了保证2A14铝合金的力学性能,通常会对其进行固溶处理,但固溶处理又会引入较大残余应力,该应力无法通过后续高温时效工艺进行消除。为此,作者对2A14铝合金依次进行(380±5)℃×120 min退火、498 ℃×2 h以及固溶和160 ℃×6 h时效处理,后进行了不同温度下的深冷+160 ℃×3 h时效处理,结合有限元模拟研究了深冷处理对试样残余应力、物相组成、微观结构、尺寸稳定性和力学性能的影响。

1. 试样制备与试验方法

试验材料为2A14铝合金锻件,尺寸为ϕ130 mm×20 mm,化学成分见表1。采用LT15/11/B410型马弗炉进行(380±5) ℃×120 min的退火处理,炉冷至150 ℃以下再空冷至室温,再进行498 ℃×2 h固溶水淬(记为固溶试样),160 ℃×6 h时效空冷(记为时效试样)处理,然后以4 ℃·min−1的速率冷却至温度分别为−70,−90,−110,−130 ℃、保温6 h进行深冷处理,冷却介质为液氮,以2 ℃·min−1的速率随炉加热至室温,最后进行160 ℃×3 h时效空冷处理(记为深冷试样)。采用Sodick AQ400LS型慢走丝线切割机将试样切成两半,获得半圆柱试样,采用Zeiss CMM CONTURA 12/18/10型高精度三坐标测试切割面轮廓尺寸并进行平均和拟合以消除误差,测试精度为2 μm,测试间距为0.25 mm。在切割面中心位置取样,经研磨、抛光、Keller试剂腐蚀10 s后,采用DMI-8C型光学显微镜(OM)和JEOL JSM 7200F型扫描电镜(SEM)观察微观形貌。采用D8 advance型X射线衍射仪(XRD)分析物相组成,铜靶,Kα射线,电压为40 kV,电流为250 mA,步长为0.05°。在切割面中心位置切取0.5 mm厚的薄圆片,用水砂纸磨至厚度为70~80 μm,用70%CH3OH+30%HNO3(体积分数)溶液双喷减薄,采用FEI Tecnai F30型透射电子显微镜(TEM)以及高分辨率模式(HRTEM)观察微观结构。

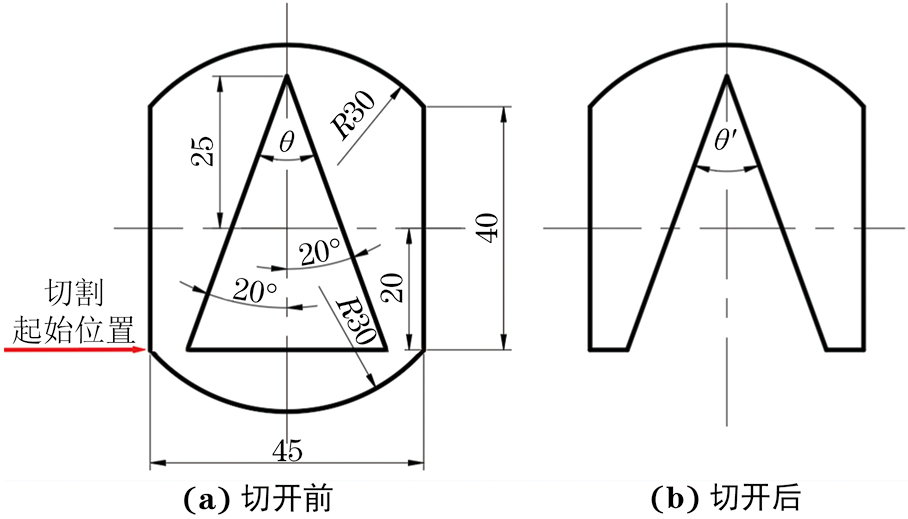

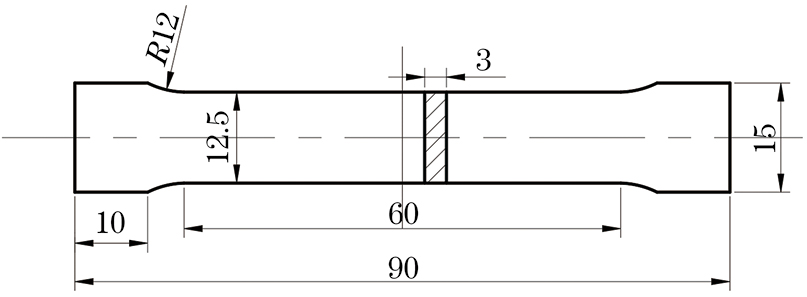

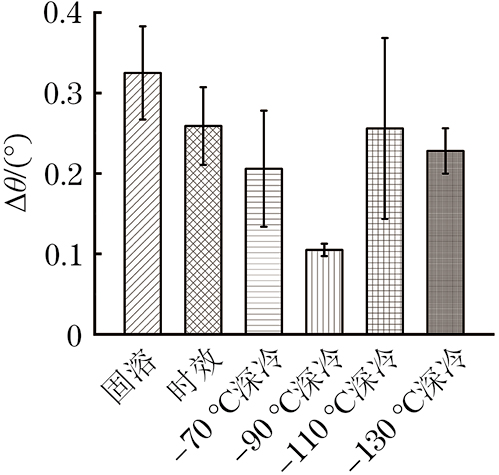

表 1 2A14铝合金的化学成分Table 1. Chemical composition of 2A14 aluminium alloy元素 Cu Mg Si Mn Ni Zn Fe Ti Al 质量分数/% 3.9~4.8 0.4~0.8 0.6~1.2 0.4~1.0 ≤0.1 ≤0.3 0~0.7 ≤0.15 余 在锻件上制取如图1(a)所示的圆环三角试样[24-25],厚度为5 mm,将其同样进行上文所述热处理后,采用高精度三坐标测量机测量θ角,采用慢走丝线切割机将其切成如图1(b)所示试样,立即测量θ´角。将θ与θ´差记为Δθ,用于评价试样的尺寸稳定性,各测3组取平均值。根据GB/T 228.1—2021,制取如图2所示的拉伸试样,采用MTS landmark 370.10型电子万能拉伸试验机进行拉伸试验,应变速率为0.000 25 s−1,各测3组取平均值。

2. 试验结果与讨论

2.1 内部残余应力

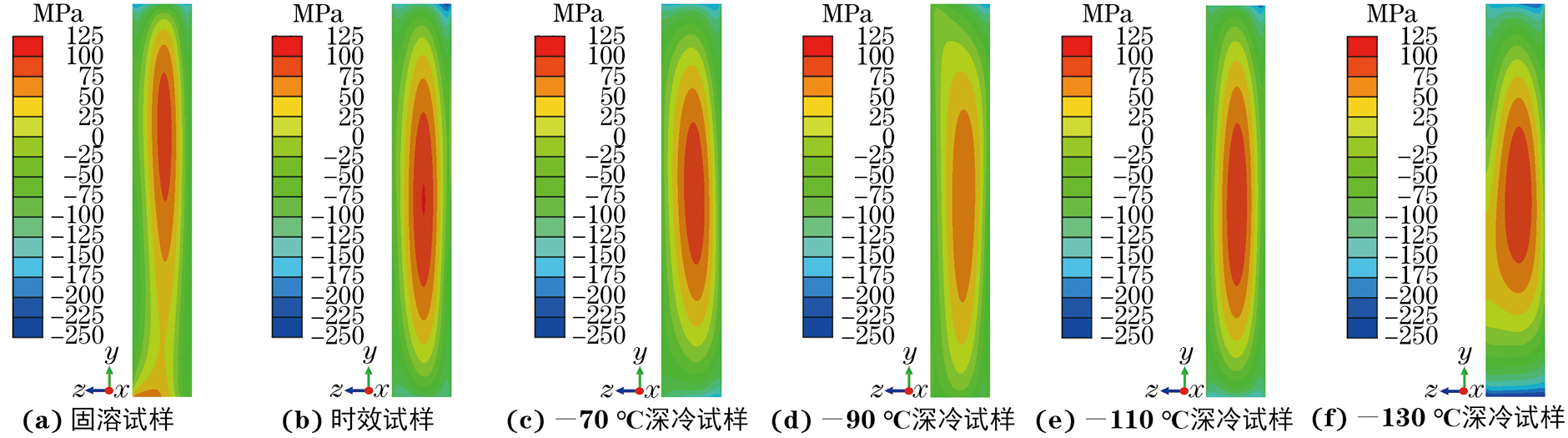

采用ABAQUS软件建立半圆柱试样的有限元模型,位移边界条件为拟合轮廓值,施加约束不影响轮廓自由变形,模拟垂直于yz切割面方向的残余应力σx在切割面上的分布[26-27]。由图3可见,不同热处理态试样切割面上的x方向残余应力均呈内拉外压形式,即试样心部为拉应力,两侧为压应力;固溶,时效,−70,−90,−110,−130 ℃深冷试样的残余拉应力峰值分别为90,101,95,74,99,99 MPa。这说明深冷处理的应力释放效果随深冷温度降低先增后减,−90 ℃下深冷处理具有最好的残余拉应力释放效果。

![]() 图 3 模拟得到不同热处理后试样切割面的残余应力分布Figure 3. Residual stress distribution on cutting faces of samples after different heat treatments obtained by simulation: (a) solid solution sample; (b) aging sample; (c) −70 ℃ cryogenic sample; (d) −90 ℃ cryogenic sample; (e) −110 ℃ cryogenic sample and (f) −130 ℃ cryogenic sample

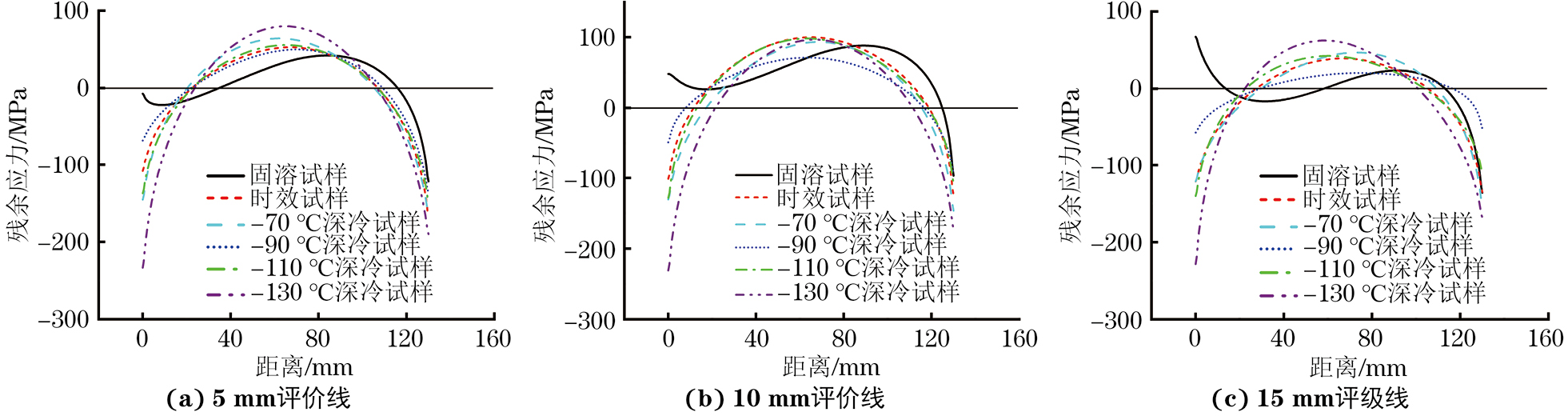

图 3 模拟得到不同热处理后试样切割面的残余应力分布Figure 3. Residual stress distribution on cutting faces of samples after different heat treatments obtained by simulation: (a) solid solution sample; (b) aging sample; (c) −70 ℃ cryogenic sample; (d) −90 ℃ cryogenic sample; (e) −110 ℃ cryogenic sample and (f) −130 ℃ cryogenic sample在距切割面边缘(平行于y轴)5,10,15 mm的位置作3条评价线,提取评价线上的残余应力绘制成图。由图4可知,除固溶试样外,其他试样均呈心部为拉应力、两侧为压应力的状态。标准差是评价样本数据离散程度的重要指标,可以用其评价不同热处理态试样切割面残余应力的均匀程度,其值越小,说明残余应力分布越均匀。以10 mm评价线数据为例,计算得到固溶,时效,−70,−90,−110,−130 ℃深冷试样的残余拉应力标准差分别为50.6,58.4,57.9,44.3,57.9,71.7。这说明深冷处理对均匀性的改善效果随温度降低先增后减,−90 ℃下深冷处理具有最好的残余拉应力均匀化效果。

2.2 物相组成与微观结构

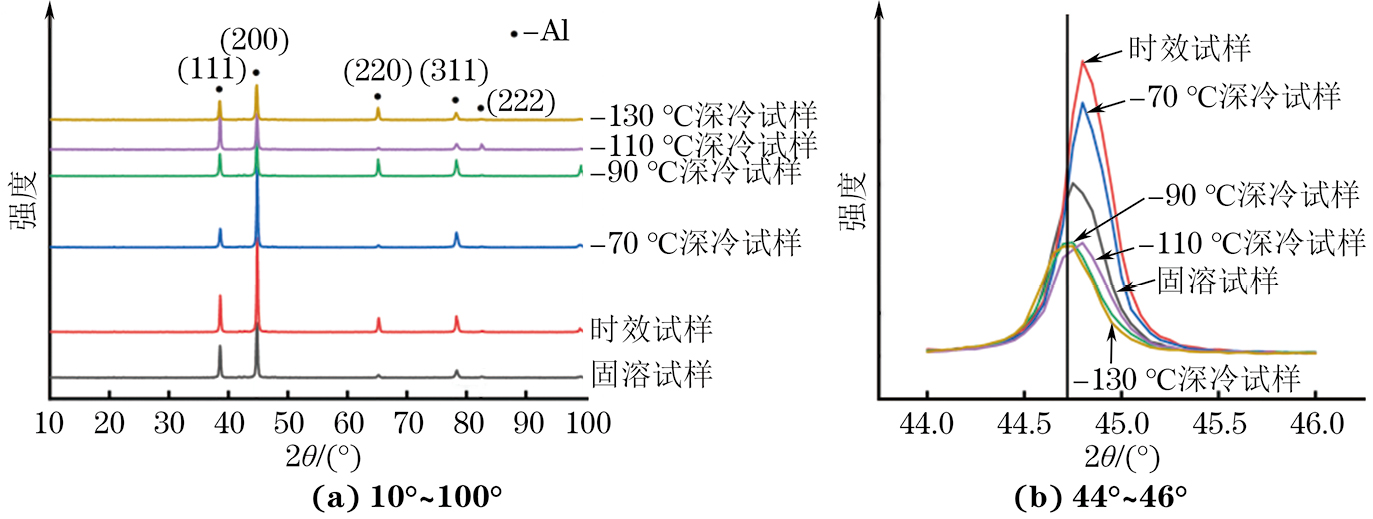

由图5可见:不同热处理后试样均由α-Al基体和Al2Cu相组成,但与标准谱相比,热处理后试样的衍射峰均发生偏移,这是因为热处理后内部残余应力的大小和分布均发生变化,导致试样发生晶格畸变,所以衍射峰发生偏移[28-29];不同试样的α-Al基体(200)晶面衍射峰半高宽不同,这与时效处理后析出相数量变化以及深冷处理后晶粒发生转动等因素有关[30-31]。固溶,时效,−70,−90,−110,−130 ℃深冷试样的(200)晶面衍射峰半高宽分别为0.325°,0.292°,0.291°,0.354°,0.358°,0.350°。半高宽可以表征晶粒大小,半高宽越大则晶粒越小。对比可知,−110 ℃深冷处理具有最好的晶粒细化效果,其次为−90 ℃深冷处理。

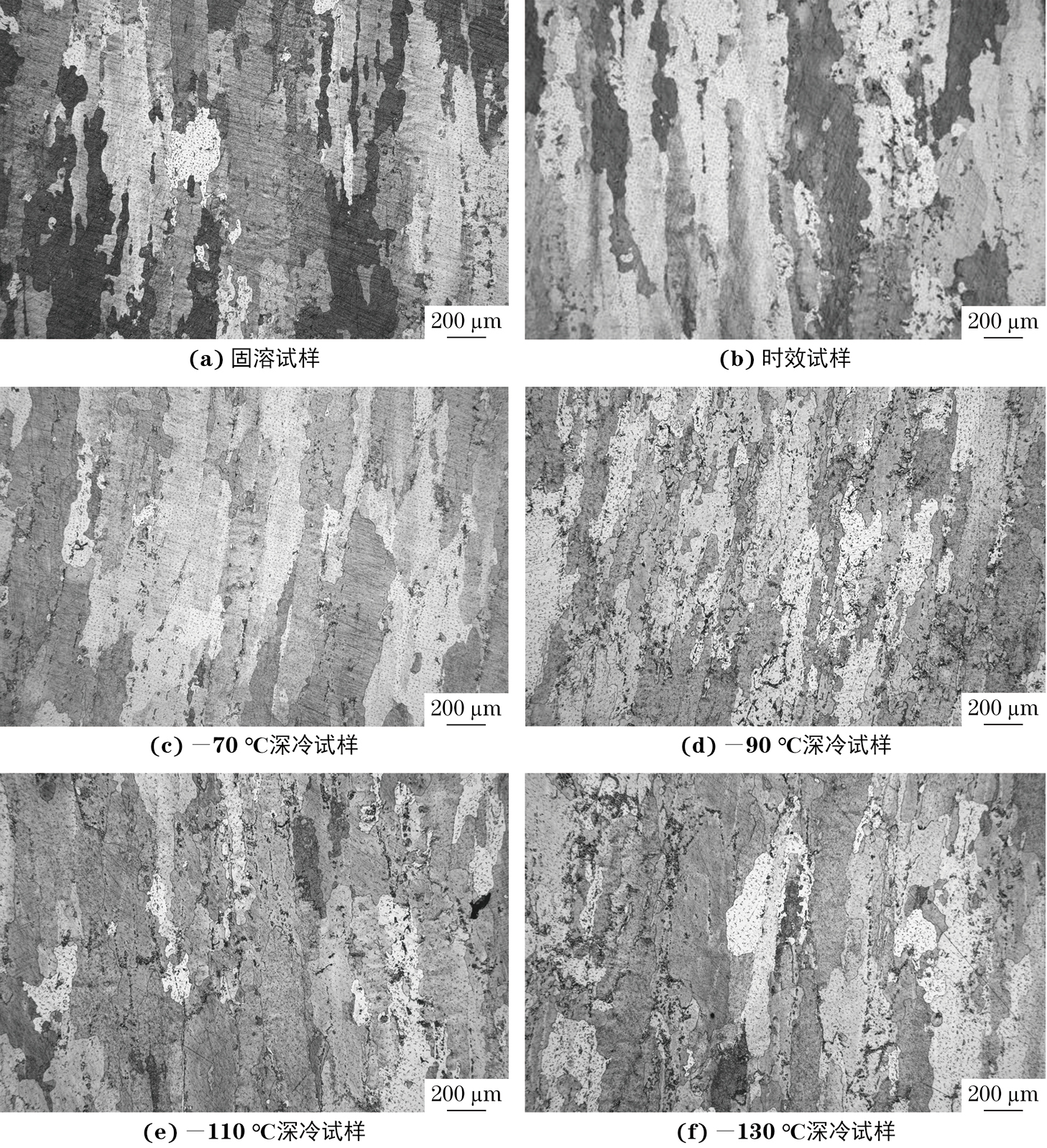

由图6可见:固溶,时效,−70 ℃深冷试样中α-Al基体相晶粒较粗大,−90,−110,−130 ℃深冷试样的晶粒较细小,与XRD分析结果相吻合。这是因为经适当温度(−130~−90 ℃)的深冷处理可以诱发晶粒转动、位错运动、应力集中等现象,从而促使2A14铝合金晶界和晶粒破碎,起到细化晶粒的作用[32]。

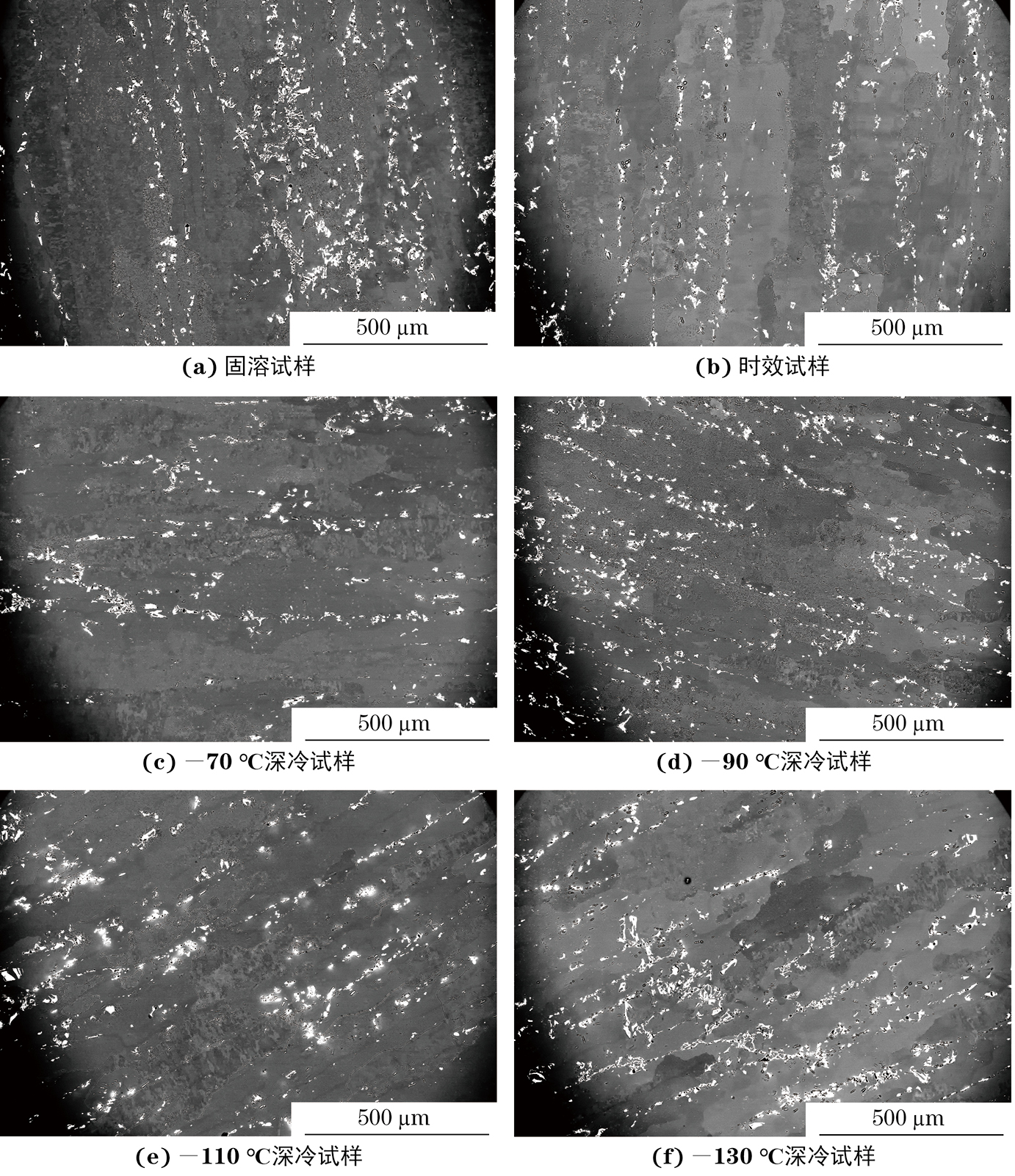

由图7可知,Al2Cu相残留在晶界或亚晶界中,弥散分布在α-Al基体中;固溶试样的Al2Cu相(白色)数量最多,但尺寸较大且大量存在聚集现象;时效,−70 ℃深冷试样Al2Cu相数量较少;−110,−130 ℃深冷试样Al2Cu相数量较多且尺寸较小,但仍少量存在聚集现象;−90 ℃深冷试样Al2Cu相数量较多、尺寸较小、弥散均匀分布在基体上。统计可得固溶,时效,−70,−90,−110,−130 ℃深冷试样Al2Cu相平均尺寸为3.96,2.79,3.26,2.53,2.80,2.81 μm,面积分数分别为3.94%,2.38%,2.26%,3.40%,2.89%,4.00%。经固溶+时效+适当温度深冷+时效的冷热循环处理后,试样晶格内的原子和空位会重新分布以保持应力平衡,这可能会提升铜和铝溶质原子结合空位的概率,提高Al2Cu相的成核速率[33];而且适当温度深冷过程中组织内部储存的应变能和吸收的低温能,能为Al2Cu相析出提供动力,这之后的时效处理又会使析出相更稳定、尺寸更细小、分布更均匀[34-36]。

结合上文可知,析出相的数量、尺寸和分布与残余应力的大小和分布紧密相关:适当温度下的深冷处理可以增加析出相数量、减小析出相尺寸、提高析出相分布弥散性,而析出相的产生会在其周围形成残余压应力场,可以抵消和均匀化拉应力。

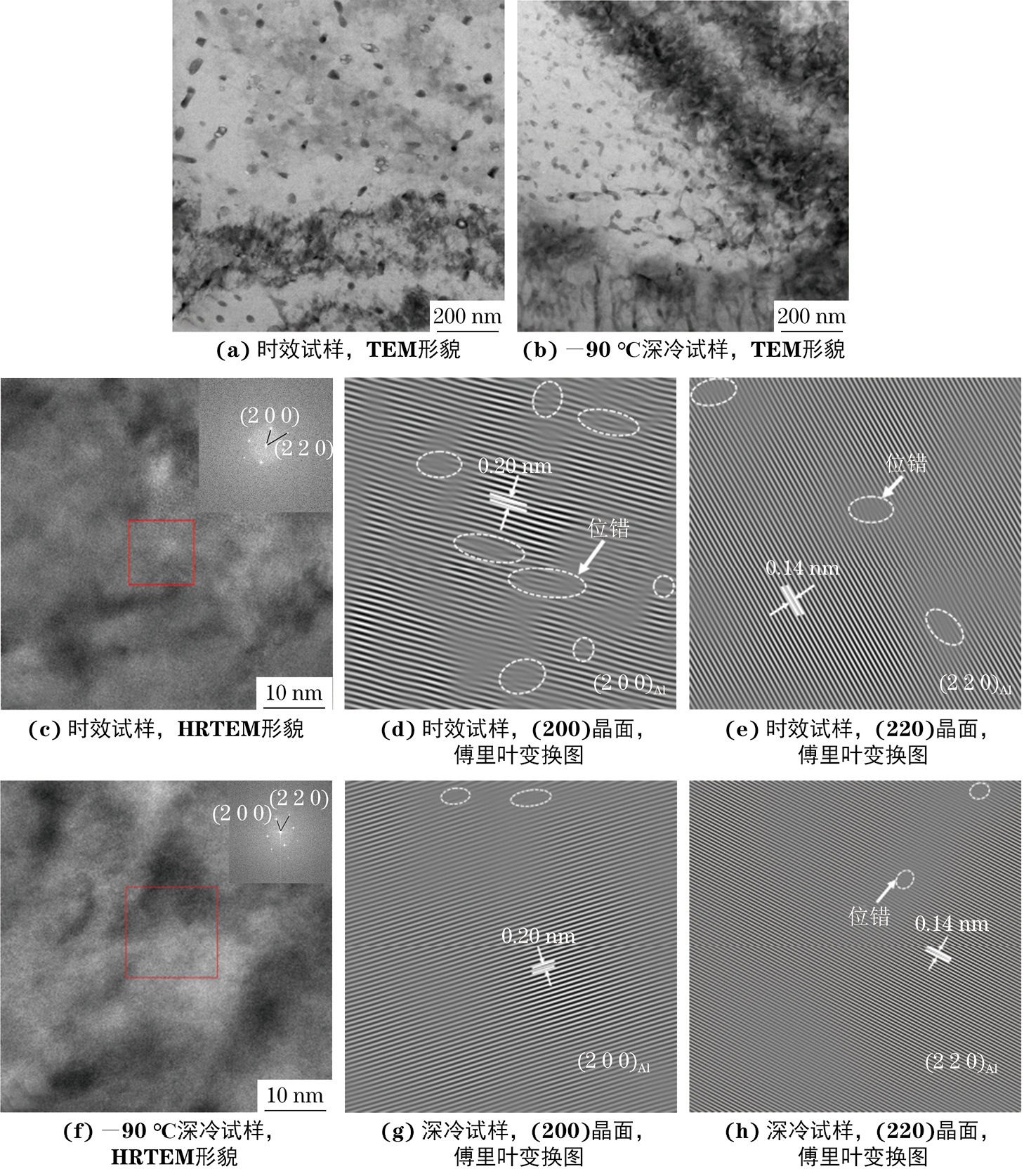

由图8可见:Al2Cu析出相主要呈短棒状和近似圆盘状。相比时效试样,−90 ℃深冷试样中的析出相和位错分布更均匀,位错密度更低,几乎不存在析出相聚集和位错缠结现象,其晶面间距未发生变化。

2.3 尺寸稳定性

由图9可见:深冷处理可以降低试样的Δθ值,提高尺寸稳定性;固溶试样的Δθ最大,尺寸稳定性最差;−90 ℃深冷试样的Δθ最小,仅为0.105°,尺寸稳定性最好。这是因为−90 ℃深冷试样中大量析出且弥散分布的Al2Cu相对位错有一定的钉扎作用,使得位错开动消耗的能量更多,所以晶格畸变减少,残余应力降低,尺寸稳定性提高[36]。

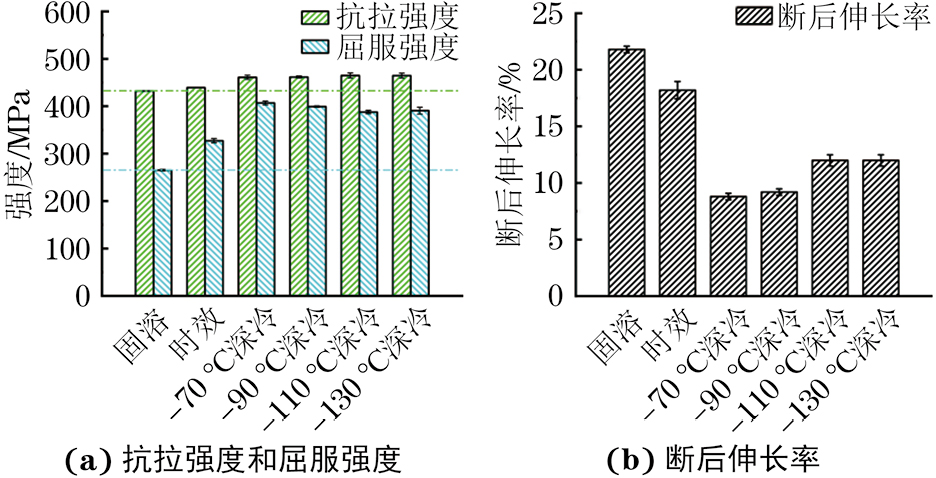

2.4 力学性能

由图10可见:深冷处理可以提高试样强度,相比固溶试样,−90 ℃深冷试样的抗拉强度和屈服强度分别提升了7%和51%,这源于深冷处理的细化晶粒作用;但是,断后伸长率降低了57%,这是因为深冷处理促进第二相析出,造成体积收缩,导致材料脆性增大、塑韧性降低[28]。

3. 结论

(1)经固溶、固溶+时效、固溶+时效+深冷处理后,2A14铝合金内部纵截面的残余应力均呈内拉外压形式,深冷处理对残余拉应力的释放效果和对应力分布的均匀化效果随温度降低均先增后减,−90 ℃下深冷处理应力释放和均匀化效果最好。

(2)不同热处理的2A14铝合金均由α-Al基体和Al2Cu相组成,−130~−90 ℃深冷处理可以细化晶粒、增加析出相数量、减小析出相尺寸、降低位错密度、提升析出相和位错分布弥散性。

(3)在固溶+时效处理后进行温度在−130~−70 ℃范围的深冷处理,可以提高2A14铝合金试样的尺寸稳定性、抗拉强度和屈服强度,但会降低断后伸长率。

-

图 3 模拟得到不同热处理后试样切割面的残余应力分布

Figure 3. Residual stress distribution on cutting faces of samples after different heat treatments obtained by simulation: (a) solid solution sample; (b) aging sample; (c) −70 ℃ cryogenic sample; (d) −90 ℃ cryogenic sample; (e) −110 ℃ cryogenic sample and (f) −130 ℃ cryogenic sample

表 1 2A14铝合金的化学成分

Table 1 Chemical composition of 2A14 aluminium alloy

元素 Cu Mg Si Mn Ni Zn Fe Ti Al 质量分数/% 3.9~4.8 0.4~0.8 0.6~1.2 0.4~1.0 ≤0.1 ≤0.3 0~0.7 ≤0.15 余 -

[1] LAN J ,SHEN X J ,LIU J ,et al. Strengthening mechanisms of 2A14 aluminum alloy with cold deformation prior to artificial aging[J]. Materials Science and Engineering:A,2019,745:517-535. [2] WANG M ,HUANG L P ,LIU W S ,et al. Influence of cumulative strain on microstructure and mechanical properties of multi-directional forged 2A14 aluminum alloy[J]. Materials Science and Engineering:A,2016,674:40-51. [3] KENT D ,SCHAFFER G B ,DRENNAN J. Age hardening of a sintered Al-Cu-Mg-Si-(Sn)alloy[J]. Materials Science and Engineering:A,2005,405(1/2):65-73. [4] WU Q ,LI L ,ZHANG Y D. Simulations and experiments on vibration control of aerospace thin-walled parts via preload[J]. Shock and Vibration,2017,2017:8135120. [5] GAO H J ,LI X ,WU Q ,et al. Effects of residual stress and equivalent bending stiffness on the dimensional stability of the thin-walled parts[J]. The International Journal of Advanced Manufacturing Technology,2022,119(7):4907-4924. [6] LI J G ,WANG S Q. Distortion caused by residual stresses in machining aeronautical aluminum alloy parts:Recent advances[J]. The International Journal of Advanced Manufacturing Technology,2017,89(1):997-1012. [7] ZHANG S Y ,WU Y X ,GONG H. A modeling of residual stress in stretched aluminum alloy plate[J]. Journal of Materials Processing Technology,2012,212(11):2463-2473. [8] GUO Z Y ,FENG Y ,NAI C G ,et al. Research on deformation control technology of back plate based on vibration aging[J]. IOP Conference Series:Earth and Environmental Science,2019,252:022118. [9] ZHANG P ,LIU J L ,GAO Y R ,et al. Effect of heat treatment process on the micro machinability of 7075 aluminum alloy[J]. Vacuum,2023,207:111574. [10] SHALVANDI M ,HOJJAT Y ,ABDULLAH A ,et al. Influence of ultrasonic stress relief on stainless steel 316 specimens:A comparison with thermal stress relief[J]. Materials and Design(1980-2015),2013,46:713-723. [11] ZOHREVAND M ,AGHAIE-KHAFRI M ,FOROUZAN F ,et al. Internal stress relief and microstructural evolution by ultrasonic treatment of austeno-ferritic 2205 duplex stainless steel[J]. Materials Science and Engineering:A,2021,815:141290. [12] ARAGHCHI M ,MANSOURI H ,VAFAEI R ,et al. A novel cryogenic treatment for reduction of residual stresses in 2024 aluminum alloy[J]. Materials Science and Engineering:A,2017,689:48-52. [13] WENG Z J ,LIU X Z ,GU K X ,et al. Modification of residual stress and microstructure in aluminium alloy by cryogenic treatment[J]. Materials Science and Technology,2020,36(14):1547-1555. [14] SHANG F X ,KONG J X ,DU D X ,et al. Effect of cryogenic treatment on internal residual stresses of hydrogen-resistant steel[J]. Micromachines,2021,12(10):1179. [15] SUN J Q ,MA Y ,GAO C ,et al. Comprehensive tensile properties improved by deep cryogenic treatment prior to aging in friction-stir-welded 2198 Al–Li alloy[J]. Rare Metals,2019:1-7. [16] CABEZA M ,FEIJOO I ,MERINO P ,et al. Effect of the deep cryogenic treatment on the stress corrosion cracking behaviour of AA 2017-T4 aluminium alloy[J]. Materials and Corrosion,2016,67(5):504-512. [17] 刘轩之,顾开选,翁泽钜,等. 铝合金深冷处理研究进展[J]. 材料导报,2020,34(3):172-177. LIU X Z ,GU K X ,WENG Z J ,et al. A review on deep cryogenic treatment of aluminium alloy[J]. Materials Reports,2020,34(3):172-177.

[18] ZHANG M L ,PAN R ,LIU B S ,et al. The influence of cryogenic treatment on the microstructure and mechanical characteristics of aluminum silicon carbide matrix composites[J]. Materials,2023,16(1):396. [19] GU K X ,WANG K K ,CHEN L B ,et al. Micro-plastic deformation behavior of Al-Zn-Mg-Cu alloy subjected to cryo-cycling treatment[J]. Materials Science and Engineering:A,2019,742:672-679. [20] LOMTE S ,DESHMUKH R ,SONAR T ,et al. Effect of deep cryogenic processing cycles on surface roughness,dimensional stability and microstructure of high carbon high chromium tool steel for cutting tool and dies applications[J]. Materials Testing,2023,65(4):629-640. [21] NIU X M ,HUANG Y ,YAN X G ,et al. Optimization of cryogenic treatment parameters for the minimum residual stress[J]. Journal of Materials Engineering and Performance,2021,30(12):9038-9047. [22] ZHOU C A ,SUN Q D ,QIAN D Q ,et al. Effect of deep cryogenic treatment on mechanical properties and residual stress of AlSi10Mg alloy fabricated by laser powder bed fusion[J]. Journal of Materials Processing Technology,2022,303:117543. [23] PRIME M B. Cross-sectional mapping of residual stresses by measuring the surface contour after a cut[J]. Journal of Engineering Materials and Technology,2001,123(2):162-168. [24] 顾开选,王凯凯,郭嘉,等. 采用圆环三角试样评价材料的尺寸稳定性[J]. 理化检验(物理分册),2021,57(6):21-26. GU K X ,WANG K K ,GUO J ,et al. Evaluation of dimensional stability of materials by ring triangular specimen[J]. Physical Testing and Chemical Analysis(Part A:Physical Testing),2021,57(6):21-26.

[25] 陈鼎,黎文献. 铝和铝合金的深冷处理[J]. 中国有色金属学报,2000,10(6):891-895. CHEN D ,LI W X. Cryogenic treatment of Al and Al alloys[J]. The Chinese Journal of Nonferrous Metals,2000,10(6):891-895.

[26] 陈鼎,夏树人,姜勇,等. 镁合金深冷处理研究[J]. 湖南大学学报(自然科学版),2008,35(1):62-65. CHEN D ,XIA S R ,JIANG Y ,et al. Study on improving performance of magnesium alloy by deep cryogenic treatment[J]. Journal of Hunan University(Natural Sciences),2008,35(1):62-65.

[27] 陈鼎,黎文献. 深冷处理下铝和铝合金的晶粒转动[J]. 中南工业大学学报(自然科学版),2000,31(6):544-547. CHEN D ,LI W X. Grain preferred orientation of Al and Al alloys through cryogenic treatment[J]. Journal of Central South University (Science and Technology),2000,31(6):544-547.

[28] 宋生,崔潆心,杨昆,等. 同步辐射白光形貌术定量计算晶体的残余应力[J]. 人工晶体学报,2013,42(12):2515-2519. SONG S ,CUI Y X ,YANG K ,et al. Quantitative calculation of the residual stress in crystal based on synchrotron radiation white beam topography[J]. Journal of Synthetic Crystals,2013,42(12):2515-2519.

[29] 付佳,晋会锦,吴素君,等. 热处理对2A14铝合金组织和性能的影响[J]. 材料热处理学报,2016,37(1):189-194. FU J ,JIN H J ,WU S J ,et al. Effect of heat treatment on microstructure and properties of 2A14 aluminum alloy[J]. Transactions of Materials and Heat Treatment,2016,37(1):189-194.

[30] 高文林,王向杰,李国爱,等. −180 ℃深冷处理对7A99铝合金峰值时效强韧性能与析出行为的影响[J]. 稀有金属材料与工程,2019,48(9):2937-2943. GAO W L ,WANG X J ,LI G A ,et al. Effect of deep cryogenic treatment of −180 ℃ on strength and toughness properties and precipitation behavior of 7A99 aluminium alloy[J]. Rare Metal Materials and Engineering,2019,48(9):2937-2943.

[31] 王岩,彭桃,张麦仓. 时效热处理消减2A02铝合金淬火残余应力的微观机理[J]. 材料热处理学报,2015,36(6):65-70. WANG Y ,PENG T ,ZHANG M C. Micro-mechanisms of quenching residual stress reduction for 2A02 aluminum alloy under aging treatment[J]. Transactions of Materials and Heat Treatment,2015,36(6):65-70.

[32] ZHANG P ,LIU Z H ,LIU J L ,et al. Effect of aging plus cryogenic treatment on the machinability of 7075 aluminum alloy[J]. Vacuum,2023,208:111692. [33] ZHANG P ,LIU Z H ,LIU J L ,et al. Effect of aging plus cryogenic treatment on the machinability of 7075 aluminum alloy[J]. Vacuum,2023,208:111692. [34] ZHOU J Z ,XU S Q ,HUANG S ,et al. Tensile properties and microstructures of a 2024-T351 aluminum alloy subjected to cryogenic treatment[J]. Metals,2016,6(11):279. [35] 宋宇峰,杨亮,丁学锋,等. 长期热暴露对Al-Cu-Mg合金微尺寸变化的影响[J]. 中国有色金属学报,2021,31(9):2412-2418. SONG Y F ,YANG L ,DING X F ,et al. Effect of long-time thermal exposure on dimensional change of Al-Cu-Mg alloy[J]. The Chinese Journal of Nonferrous Metals,2021,31(9):2412-2418.

[36] ZHU W X ,ZHAO F ,YIN S ,et al. Effect of tensile deformation on residual stress of GH4169 alloy[J]. Materials,2021,14(7):1773.

下载:

下载: