Hydrogen Embrittlement Behavior of Mixed Hydrogen Natural Gas Pipeline Steel: A review

-

摘要:

近年来,利用现有的天然气管网输送氢气以其经济性和高效性受到国内外研究学者的广泛关注。但是,氢气导致管线钢的氢脆问题给管道的长期安全运行带来极大的挑战,掺氢天然气输送管线钢的氢脆行为研究迫在眉睫。综述了金属氢脆机理的研究进展,对氢气/掺氢天然气环境中管线钢金属力学性能变化等方面的研究现状进行总结。此外,还介绍了抑制管线钢氢脆行为的常用方法,为氢脆问题的有效解决提供参考,从而保障天然气输送管道的安全运行。

Abstract:The economical and efficient of using existing current natural gas pipelines for hydrogen transportation has garnered domestic and foreign researchers in recent years. However, the problem of hydrogen embrittlement in pipeline steel caused by hydrogen poses a great challenge to the long-term safe operation of pipelines, and research on the hydrogen embrittlement behavior of pipeline steel for hydrogen doped natural gas transportation is urgently needed. The research progresses on the mechanism of metal hydrogen embrittlement were reviewed and the current research status on the changes in mechanical properties of pipeline steel under hydrogen/hydrogen doped natural gas environments were summarized in this article. In addition, common methods for suppressing hydrogen embrittlement behavior in pipeline steel were introduced, and the reference for effective solutions to hydrogen embrittlement problems were provided to ensure the safe operation of natural gas transmission pipelines.

-

随着全球能源需求量不断增长,由此带来的化石燃料短缺和环境污染问题日益严峻,国内外都在积极寻找其替代和补充品。氢是一种清洁可持续发展的能源,利用现有的天然气管网输送氢气是现有的氢能储运技术中最高效和经济的方式之一。包括美国、日本等在内的许多国家已经开展了天然气掺氢项目[1-5],形成了多项测试和评价方法[6-7]。中国能源企业也开始了掺氢天然气管网的尝试和部署[8]。但管线钢在输送含氢介质时,介质中的氢气分子会与钢材表面碰撞并吸附于钢材表面,随后以原子形式渗入钢材,使管线钢发生氢致开裂和氢鼓泡,力学性能下降,甚至引起管线突然失效[9-12]。

为解决掺氢天然气管道输送的安全问题,国内外正积极开展中低压、高压纯氢与掺氢天然气管道应用安全技术研究,力图突破天然气掺氢技术瓶颈,积累天然气掺氢与管道适应性的相关数据,加快氢能管道发展。近年来为了研究氢与管线钢的相容性,已进行了许多试验[3,13-21]。NGUYEN等[18]研究发现氢气环境会降低X70管线钢的塑性和断裂韧性;AN等[22-23]和ZHANG等[20,24-25]的研究表明,X80管线钢在氢环境中表现出疲劳裂纹扩展速率(FCGR)增加,断裂韧性下降,疲劳寿命降低。这些性能变化给管道的安全运行带来隐患,目前需要建立管线钢氢脆行为的机制理论,明确其产生氢脆行为后的性能变化规律,保障输气管道安全运行,并寻求有效的抗氢脆方法。

笔者从氢脆机理,管线钢氢脆敏感性及抗氢损伤方法等方面阐述了管线钢氢脆问题的研究现状及进展,对管线钢氢脆行为进行归纳整理,以期加快明确氢对管线钢性能的影响规律及作用机制,为保障氢气输送管道的安全运行、有效解决氢脆问题提供参考。

1. 金属氢脆机理

目前,铁基金属材料氢脆机制主要有氢压理论、氢致局部塑性变形理论(HELP)、氢降低表面能理论和氢致弱键理论(HEDE)。金属材料氢脆机理的相关研究已有近百年,关于氢进入金属及存在方式、迁移与聚集过程和氢引起金属材料力学性能改变等方面的认识已趋于一致,但没有一个确切的机制可以理清所有观测到的氢脆现象。近年来,随着检测技术的发展,一些研究结果支撑了以上氢脆理论,比如,一些学者通过透射电镜(TEM)和纳米压痕试验发现氢降低位错发射阻力,促进钢中的位错运动[26-27],CHEN等[28]利用原子探针成像(APT)技术观测到了氘在位错中心处、晶界处和夹杂物界面处的偏析,为HELP理论和HEDE理论提供了试验支撑。最近,也有研究人员提出了新的氢脆理论,GONG等[29]研究发现富氢样品有更高的位错迁移率,氢促进位错纳米结构的形成,位错纳米结构又充当了氢的新捕获位点,获得更多的氢产生严重的位错裂纹,导致局部应变分配和破坏。

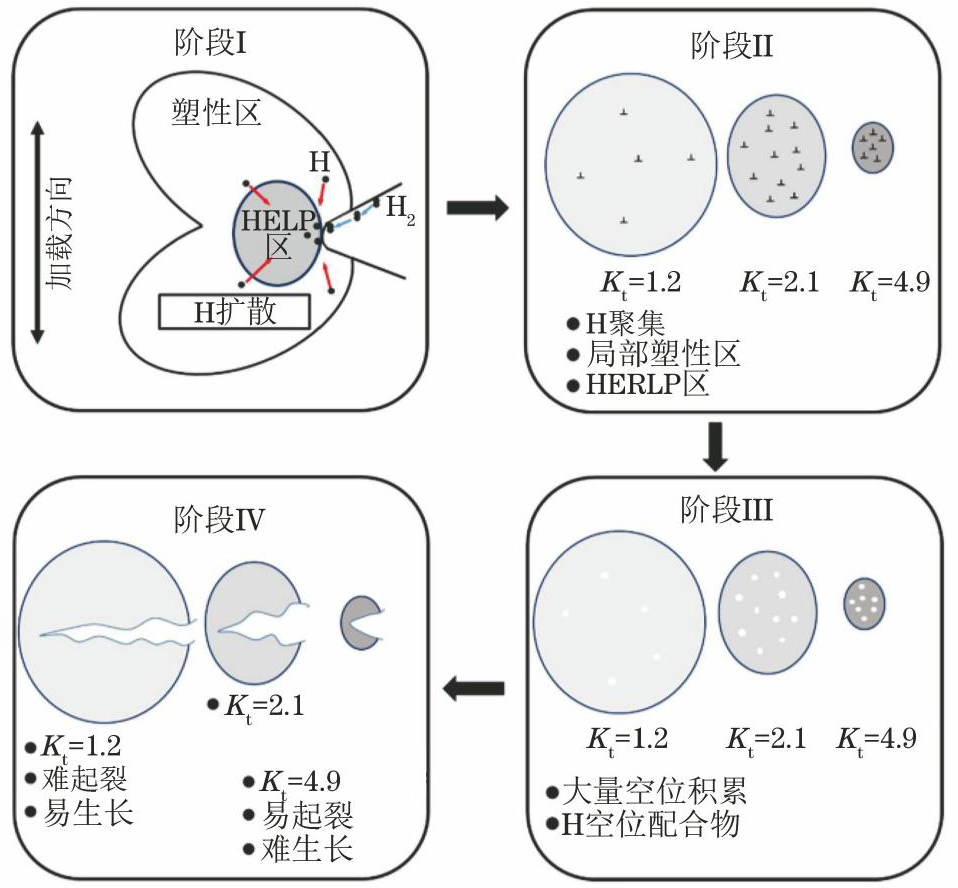

以上氢脆理论各有长短,在研究和解决实际材料的氢脆问题时通常需要综合以上理论分析,获得更为合理的解释。AN等[30]对氢气和应力集中对X80管线钢疲劳寿命损伤的协同作用机理进行分析,认为氢致疲劳性能损伤的过程分为四个阶段,如图1所示。氢脆过程的第一步是氢原子从环境进入材料高应力集中区域,氢原子的富集形成高氢压的局部塑性区。由于缺口引起的应力集中对载荷十分敏感,因此在应力集中区域有利于塑性变形,这个氢含量高的局部变形区域即为HELP区域[31]。第二阶段,局部塑性变形和局部氢含量随着应力集中的增加而增加,HELP区域的面积减少。在此后的阶段,过多的空位形成并在HELP区域累积,这些空位引起纳米微孔形核并导致裂纹的形成。由于高局部塑性变形和高局部氢含量,裂纹萌生的循环次数随着应力集中的增加而降低。疲劳裂纹不仅从缺口处开始萌生,而且裂纹的扩展也受到缺口引起的应力集中的影响。当应力集中系数低时,裂纹难以萌生但是裂纹扩展速率可能会很快;当应力集中系数高时,裂纹容易萌生,但是其扩展速率相对较低。

2. 管线钢氢脆敏感性

氢脆敏感性指材料在含氢环境中发生氢脆的倾向[32-34]。氢原子经吸附、吸收和扩散的方式进入材料内部后,通常使材料塑性、韧性、疲劳强度等性能显著下降,材料的断裂行为从韧性断裂转变为脆性断裂。以往研究大多是在液体环境中进行的,掺氢天然气管道的氢脆发生在气体环境中,氢原子产生的机理是氢分子在管线钢表面的吸附解离,并且材料晶格和陷阱中捕获的氢在特定的氢压条件下相对稳定[35],与液态氢有本质区别。因此,近年来采用气态环境中的管线钢氢脆敏感性试验,如慢应变速率试验(SSRT)、断裂韧性试验、和疲劳寿命试验等,可以更准确地研究掺氢天然气用管线钢的氢脆行为。大量研究表明,氢脆敏感性会随着管线钢等级的提高和氢气压力的增加而增大[36-37],氢脆失效风险也会进一步提高。

2.1 氢对管线钢塑性及韧性的影响

原位气态氢环境中的SSRT和断裂韧性试验是目前研究管线钢氢脆敏感性的主要手段。氢脆指数(IE)可以反映材料在氢环境中的氢脆敏感性程度,氢脆指数按照(1)式计算:

(1) 式中:L0、LH分别为试样在不含氢和含氢环境中经SSRT后的断后伸长率。通常情况下随着氢压的升高,X42~X100管线钢的氢脆指数都呈上升趋势,并且氢脆指数与管线钢的强度有一定联系,管线钢的强度越高其氢脆敏感性越强[21,37-42]。

李玉星等[38]在4 MPa气体总压下掺入0~2 MPa氢气的环境中对X52管线钢进行了SSRT,发现其屈服强度、抗拉强度变化不大,断后伸长率、断面收缩率随氢分压增大而逐渐下降,氢脆指数逐渐上升,最大为13%,小于工程上的氢脆阈值。刘方等[39]研究发现X65管线钢在含氢环境中也出现氢脆现象,在总压为9 MPa,含氢量(质量分数)3%、5%、10%气体环境中其屈服强度、抗拉强度出现了小幅下降,断后伸长率随掺氢比例的增大而逐渐下降,氢脆指数最高达11.63%。并且随着掺氢比例的增大,裂纹尖端张开位移逐渐减小,试样断裂韧性逐渐降低。

X70钢是被世界各国广泛使用的高钢级管线钢,关于其氢脆行为也有大量研究。在氢含量较小的情况下,X70钢的氢脆敏感性并不明显,关鸿鹏等[43]和李天雷等[44]等测试了X70钢母材和焊缝分别在含有0.2 MPa和0.36 MPa氢气环境中的力学性能,发现X70钢母材和焊缝的冲击性能、塑性延伸率以及材料的损伤容限均未受到明显影响,断裂韧性的劣化程度也在10%以内。而一些学者持不同的观点,ALVARO等[45]、NGUYEN等[14,18,21]及SHANG等[46]的研究都指出在含有少量氢气(0.1 MPa)时,X70钢母材的塑性没有发生下降,但其焊缝的塑性明显降低且母材和焊缝的断裂韧性都显著降低,而在10 MPa或更高的高压纯氢气中,X70钢的塑性和韧性劣化程度大幅增加。NGUYEN等[40]还对X42、X65和X70三种管线钢在不同混合氢含量条件下的力学性能进行了比较,发现在含30%(质量分量)H2的H2/CH4混合气体中观察到了氢辅助脆性断裂现象,随着氢含量的增加,试样的断后伸长率和断面收缩率都有明显下降和上升。

关于X80管线钢的氢脆行为,研究人员也得到了与X52-X70钢相似的结论,即在混合气体中掺入氢气(0~20%)对X80钢的屈服强度和抗拉强度影响不大,但塑性有所下降[19,23,24,38,47-48]。BRIOTTET和MORO等[41,49-50]还指出当氢分压为0.1~5.0 MPa时,X80钢的塑性随氢分压增大而显著降低,但当氢分压超过5 MPa后,X80钢的塑性变化趋于平稳,当氢分压为10~30 MPa时几乎不变,在30 MPa氢分压下,X80钢的断裂韧性较在空气中下降90%以上。目前,也有学者对X100管线钢的氢脆行为进行了研究,NANNINGA等[37]研究发现气态氢对X100管线钢屈服强度和抗拉强度均无显著影响,但会显著降低其断后伸长率和断面收缩率,并且氢脆敏感性随管线钢强度的增大而增大。AMARO等[42]对X52钢和X100钢在13.8 MPa氢气环境中的拉伸试验也得到了相似的结果。RONEVICH等[51]在21 MPa氢气条件下对X52电阻焊、X100搅拌摩擦焊和X52、X65、X100气体金属电弧焊等不同强度等级和焊接工艺的管道焊缝进行了断裂韧性测试,发现随着屈服强度的增加,试样的断裂韧性呈下降趋势。

2.2 氢对管线钢疲劳性能的影响

疲劳裂纹扩展速率是评价管线钢氢脆行为的重要参数[36,52-55],氢对管线钢疲劳性能的影响主要体现在氢加速了疲劳裂纹萌生和扩展以及疲劳寿命的改变。当应力强度因子超过一个临界值

时,氢能加速材料的疲劳裂纹扩展速率(FCGR),但是

时,氢能加速材料的疲劳裂纹扩展速率(FCGR),但是 受材料、氢气压力以及加载条件的影响。

受材料、氢气压力以及加载条件的影响。

金属疲劳一般分疲劳裂纹萌生阶段、疲劳裂纹扩展阶段、疲劳断裂阶段三个阶段,近年来关于管线钢FCGR的研究主要集中在疲劳裂纹扩展阶段。李天雷等[44]研究表明X70钢热影响区在0.36 MPa氢分压下的FCGR比在空气环境中的高了一个数量级,且断裂表面为解理断裂。RONEVICH等[55-56]研究发现,X52和X100试样在氢气(21 MPa)中的裂纹扩展速率显著高于在空气中的。文献[52]指出氢气会使X52管线钢的FCGR增加,但不随氢压的增加而变化,而X80和X100等管线钢裂纹扩展速率随氢压增大而加大。SLIFKA等[53]的研究也证实了这一说法,他认为X100和X52管线钢在加压氢环境中(氢压为1.7,7,21,48 MPa)的FCGR比在空气中的高一到两个数量级,但X52钢在不同氢压下显示出相近的裂纹扩展速率,而X100钢的FCGR随着氢压的增大而增大。DREXLER等[57]的研究也表明,X52和X70管线钢的母材、焊缝和热影响区在含氢环境中的FCGR都比在空气环境中的高,但氢压对裂纹扩展速率的影响不大。AN等[22]研究了X80管线钢在氢环境中的低周疲劳和疲劳裂纹扩展行为,发现裂纹扩展速率取决于氢压。SHI等[58]研究了高强度管线钢的氢致开裂行为,发现氢的存在会加速高强度管线钢的开裂,X70和X80级管线钢具有较好的抗氢致开裂性能,而X90和X100级管线钢的抗氢致开裂性能相对较差。大量的研究结果表明在含氢条件下,少量的氢就会导致管线钢的裂纹扩展速率显著增加,但随着氢压的升高,氢对管线钢裂纹扩展的加速作用减弱。

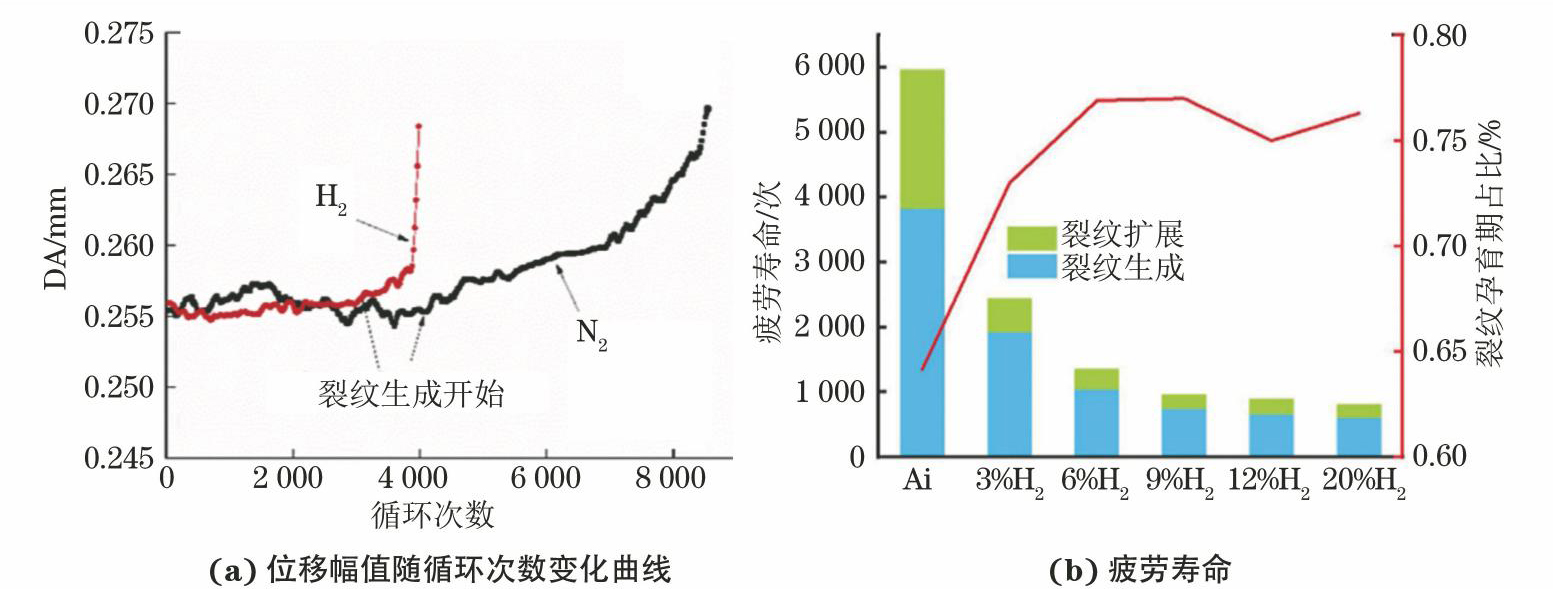

疲劳寿命测试也是研究管线钢氢脆影响一种常用手段。如图2所示,AN等[22]的研究表明,含氢环境会对X80管线钢的疲劳性能造成损伤,在0.6 MPa的低氢压环境中,缺口试样的低周疲劳寿命随着氢压的增加而降低,当位移幅值(DA)稳定(低于3 000次循环)时,X80钢在含氢和不含氢条件下的疲劳性能均未出现明显的恶化,随着DA的增加(约为3 000次循环左右),在含氢环境中裂纹开始萌生并在1 000次循环后裂纹快速扩展,疲劳性能严重受损,而在氮气环境中进行4 000次循环后,裂纹开始萌生,超过7 000次后裂纹开始快速扩展,含氢环境会加速裂纹的萌生,增加裂纹扩展速率。ZHUO等[25]和MENG等[19]的研究也得到了相似的结论,即随着氢分压的增加,疲劳寿命下降且下降趋势逐渐趋于平缓。

3. 管线钢氢脆的抑制方法

3.1 添加抑制剂气体

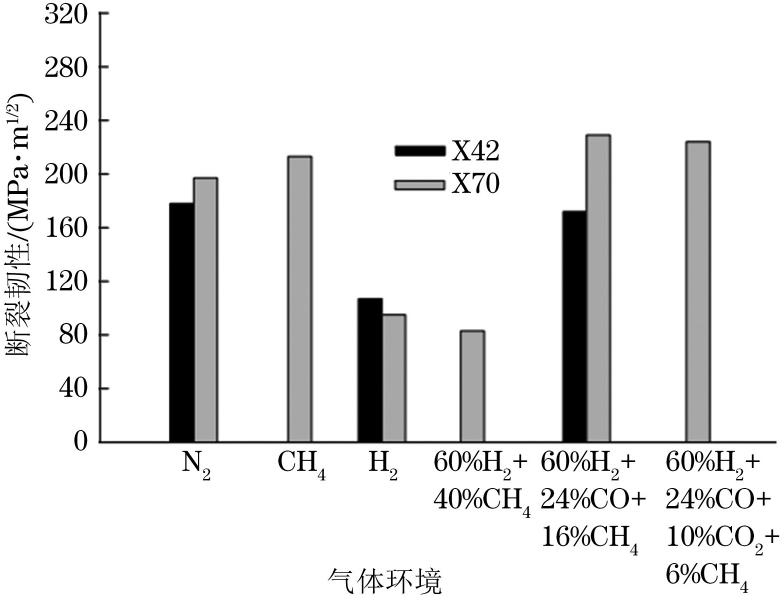

氢含量及环境因素对管线钢氢脆敏感性有较大影响,近年来研究者们开展了含氢混合气体对管线钢力学性能影响的研究。甲烷、一氧化碳、二氧化碳等气体组分对管线钢断裂韧性的影响如图3所示[59]。可以看出,相比于在氮气中的结果,管线钢在6.9 MPa氢压条件下的断裂韧性(JIC)下降了一半,一氧化碳为有效抑制剂气体,当含氢气体中混入一氧化碳,管线钢的断裂韧性恢复到氮气中的水平,而甲烷气体对断裂韧性无影响。

SHANG等[3]研究发现,低碳钢会吸附天然气中的CO2,且CO2和H2的相互作用会加速金属的裂纹扩展。MENG等[19]研究发现,X80管线钢对甲烷和H2混合气体敏感,且敏感性随着氢气组分的增加而增加。为了减少氢对管线钢的损伤,对含氢气体环境改性的常用方法是使用抑制剂。在高纯氢气中,少量氧就会减缓材料的氢脆。KOMODA等[60]的研究证实在氧质量浓度低于0.1 mg/L的氢气混合气体中,管线钢的断裂韧性显著降低,添加100 mg/L氧气可完全抑制氢引起的断裂韧性退化。MICHLER等[61]研究了O2对高强度珠光体钢和奥氏体钢氢脆敏感性的影响,发现低压氧的存在显著降低了钢的氢脆行为,其中氧分压是氧抑制氢脆作用的主因,其次是温度,温度的降低和氢压的升高会导致氧对氢脆抑制作用下降。SOMERDAY等[52]测试了O2对X52管线钢FCGR的影响,发现在测试初期,钢在高纯氢气和氢氧混合气中的FCGR基本一致,之后随着ΔK增加,裂纹扩展突然加速。其中,裂纹开始加速扩展的ΔK值随着混合气中氧含量的增加而增加。

3.2 控制氢含量和温度

管线钢的充氢时间,充氢方式及放置时间都会导致其中的氢含量不同,进而造成管线钢氢脆敏感性的差异[62]。ZHANG等[24]研究了氢分压对管线钢断裂韧性和疲劳寿命的影响机理,结果显示随着氢压的增加,氢渗透稳态电流密度升高,即通过材料内部的氢原子数量越来越多。根据前文所述的HEDE理论,氢会引降低材料的原子间结合力。因此,AN等[22]和ZHANG等[20]认为X80钢临氢时裂纹扩展速率取决于氢气压力,在裂纹尖端聚集的氢原子越多,越容易引起原子间的结合力降低。ZHOU等[63]研究表明,X80管线钢的氢脆受内部氢和表面吸收氢的影响,表面吸收氢因其有效氢浓度较高而起主要作用且氢脆主要由位错俘获氢的行为决定。

温度升高会导致氢的扩散系数增大,溶解度下降,但目前关于温度对管线钢氢脆敏感性影响的认识还不明确,有研究者认为温度升高会加速氢扩散,降低位错捕氢能力,氢浓度达不到临界值,低温条件下,扩散系数小,在形变过程中氢来不及扩散富集,也不会造成氢脆,因此只有在一定的温度范围内,金属才会有氢脆敏感性[64]。XU等[65]采用原位气态氢渗透试验和SSRT,研究了X52管线钢在20~60 ℃(天然气管道常见工作温度)的氢扩散行为和氢脆敏感性,发现温度的升高显著提高了氢的扩散速率,在2 MPa氢压条件下,X52钢的氢脆指数从20 ℃时的7.17%增加到60 ℃时的17.29%。XING等[66]研究了X90钢氢脆与温度的关系,结果表明,X90钢的氢脆温度阈值为313 K,超过该阈值,氢脆随温度升高而减弱,低于该阈值,氢脆随温度升高而增强。

3.3 增加管线钢表面物理屏障

增加物理屏障即在金属表面沉积涂层,可以显著降低金属的氢脆行为。涂层包括氧化物层如Al2O3、TiO2和Cr2O3等和电镀层如Ni、Cd和Sn等,以及喷镀层等如TiC、TiN、BN和WC等。在要保护的材料表面选择合适的涂层来阻隔或降低外界氢介质进入材料内部的过程包括降低材料表面活性以降低氢介质在材料表面的吸附分解速率;抑制氢原子或离子在涂层内部的扩散等。SHI等[67]将碳注入管钢表面预先沉积的镍催化层中,然后退火离析形成多层石墨烯,SSRT结果表明,该涂层具有优异的抗氢脆性,因为涂层抑制了氢的析出,延长了扩散路径,减小了渗透面积,并增强了氢的吸附从而在相同外界条件下,减少进入材料内部的氢含量,降低材料的氢损伤程度。但是涂层也存在一定的缺陷,如孔洞、微裂纹等,这些缺陷区域易成为氢原子等进入的快速通道,并产生氢致裂纹。喷丸处理也能提高材料的抗氢脆能力。喷丸技术是一种表面改性技术,通过硬质球在材料表面轰击产生残余压应力,延迟裂纹的萌生并阻碍裂纹的扩展[68],喷丸处理增加了裂纹萌生需要的能量,并抑制了试样内己经存在裂纹的扩展。

3.4 避免应力集中

应力集中可能出现在管道的某些部分,如弯管、丁字支管和焊接接头,应力集中影响氢在管线钢中的传输和分布,进而影响钢在含氢环境中的力学性能。缺口试样是评价氢气环境中应力集中对钢力学性能影响的有效工具。许多研究表明在氢和应力集中的协同作用下,X70和X80管线钢试样的缺口尖端俘获的氢最多,且并随着Kt(应力集中系数)的增加而增加[46,69-71]。ZHANG等研究表明,拉伸试验时,试样断裂发生在Kt较低的缺口处,而在疲劳寿命试验期间,试样在Kt较高的缺口处断裂,双缺口试样的断裂可能由塑性变形引起的应力集中和应变硬化引起,当应力处于较低水平时,应力集中效应比应变硬化更显著,断裂发生在应力集中系数较高的位置。然而对于X80管线钢等高强度钢,当应力处于高水平时,塑性变形导致应变强化而使其强度更高。因此,在管线钢使用前,材料设计必须适当,必须避免缺口、尖锐和规则变化,并在加工前消除残余应力。

4. 结束语

当今世界,能源领域已经形成煤炭、石油、天然气、新能源“四分天下”的新格局,能源清洁化利用是趋势[72]。氢能是一种无污染的能源,氢气的燃烧能够实现碳的零排放,因而受到高度重视。目前较为高效和经济的氢能运输方式是将氢气按照一定比例混入天然气中,利用现有天然气管网进行输送。然而,管线钢的氢脆问题不容忽视,怎样保证管道安全稳定运行,减少氢脆引起的材料性能下降,不发生因氢气存在而导致管线发生断裂的事故,是目前亟待解决的问题。

基于国内外文献调研,详细总结和讨论了金属氢脆机理,气体氢和天然气掺氢环境对管线钢塑性韧性、疲劳性能的影响,并讨论了管线钢氢脆抑制方法的研究进展。虽然目前国内外学者已经进行了氢气环境中管线钢材料的氢相容性研究,但仍有许多技术和安全性方面的问题制约了氢能经济的发展,如对于HEDE机制,虽然已有理论计算数据,但缺乏局部氢浓度和原子成键相互作用之间定量关系的试验证明;氢气对管线钢产生氢脆后力学性能的变化规律还不明了;目前还没有能够有效抑制或防止管线钢氢脆发生的防护措施。因此,需建立起管线钢发生氢脆的机制,同时对管线钢与氢环境的相容性进行充分评估,即对氢原子进入材料内部后,材料的力学性能发生的变化进行充分研判。此外,还应充分分析影响管线钢氢脆行为的因素,以此为基础寻求抑制管线钢氢损伤的方法,为输氢管道的安全运行提供安全保障。

-

-

[1] APREA J L, BOLCICH J C. The energy transition towards hydrogen utilization for green life and sustainable human development in Patagonia [J]. International Journal of Hydrogen Energy, 2020, 45(47):25627-25645. [2] 任若轩, 游双矫, 朱新宇, 等. 天然气掺氢输送技术发展现状及前景 [J]. 油气与新能源, 2021, 33(4):26-32. REN R X, YOU S J, ZHU X Y, et al. Development status and prospects of hydrogen compressed natural gas transportation technology [J]. Petroleum And New Energy, 2021, 33(4):26-32.

[3] SHANG J, CHEN W F, ZHENG J Y, et al. Enhanced hydrogen embrittlement of low-carbon steel to natural gas/hydrogen mixtures [J]. Scripta Materialia, 2020, 189:67-71. [4] 李凤, 董绍华, 陈林, 等. 掺氢天然气长距离管道输送安全关键技术与进展 [J]. 力学与实践, 2023, 45(2):230-244. LI F, DONG S H, CHEN L, et al. Key safety technologies and advances in long-distance pipeline transportation of hydrogen blended natural gas [J]. Mechanics in Engineering, 2023, 45(2):230-244.

[5] 陈林, 董绍华, 李凤, 等. 氢环境下压力容器及管道材料相容性研究进展 [J]. 力学与实践, 2022, 44(3):503-518. CHEN L, DONG S H, LI F, et al. Some advances in studies of material compatibility of pressure vessels and pipelines in hydrogen atmosphere [J]. Mechanics in Engineering, 2022, 44(3):503-518.

[6] 邢云颖, 赵茜, 王修云, 等. 掺氢天然气输送管道材料适用性的测试方法 [J]. 腐蚀与防护, 2023, 44(9):51-56,106. XING Y Y, ZHAO Q, WANG X Y, et al. Test method for suitability of hydrogen-doped natural gas transport pipeline materials [J]. Corrosion & Protection, 2023, 44(9):51-56,106.

[7] 孔莹莹, 崔继彤, 韩辉, 等. 国内外氢气管道输送技术标准对比与探讨 [J]. 油气储运, 2023, 42(8):944-951. KONG Y Y, CUI J T, HAN H, et al. Comparative analysis and discussion on domestic and foreign technical standards for hydrogen pipeline transportation [J]. Oil & Gas Storage and Transportation, 2023, 42(8):944-951.

[8] 张烘玮, 赵杰, 李敬法, 等. 天然气掺氢输送环境下的腐蚀与氢脆研究进展 [J]. 天然气工业, 2023, 43(6):126-138. ZHANG H W, ZHAO J, LI J F, et al. Research progress on corrosion and hydrogen embrittlement in hydrogen-natural gas pipeline transportation [J]. Natural Gas Industry, 2023, 43(6):126-138.

[9] NAGUMO M, TAKAI K. The predominant role of strain-induced vacancies in hydrogen embrittlement of steels: Overview [J]. Acta Materialia, 2019, 165:722-733. [10] 程玉峰. 高压氢气管道氢脆问题明晰 [J]. 油气储运, 2023, 42(1):1-8. CHENG Y F. Essence and gap analysis for hydrogen embrittlement of pipelines in high-pressure hydrogen environments [J]. Oil & Gas Storage and Transportation, 2023, 42(1):1-8.

[11] LI H Y, NIU R M, LI W, et al. Hydrogen in pipeline steels: recent advances in characterization and embrittlement mitigation [J]. Journal of Natural Gas Science and Engineering, 2022, 105:104709. [12] DJUKIC M B, BAKIC G M, SIJACKI ZERAVCIC V, et al. The synergistic action and interplay of hydrogen embrittlement mechanisms in steels and iron: localized plasticity and decohesion [J]. Engineering Fracture Mechanics, 2019, 216:106528. [13] ZHANG T M, ZHAO W M, LI T T, et al. Comparison of hydrogen embrittlement susceptibility of three cathodic protected subsea pipeline steels from a point of view of hydrogen permeation [J]. Corrosion Science, 2018, 131:104-115. [14] NGUYEN T T, TAK N, PARK J, et al. Hydrogen embrittlement susceptibility of X70 pipeline steel weld under a low partial hydrogen environment [J]. International Journal of Hydrogen Energy, 2020, 45(43):23739-23753. [15] SHANG J, WANG J Z, CHEN W F, et al. Different effects of pure hydrogen vs. hydrogen/natural gas mixture on fracture toughness degradation of two carbon steels [J]. Materials Letters, 2021, 296:129924. [16] CHEN K, ZHAO W, XIAO G C, et al. Corrosion characteristics of simulated reheated heat-affected-zone of X80 pipeline steel in carbonate/bicarbonate solution [J]. Corrosion Science, 2023, 210:110856. [17] CHEN K, ZHAO W, XIAO G C, et al. Study on corrosion resistance and hydrogen permeation behavior in inter-critically reheated coarse-grained heat-affected zone of X80 pipeline steel [J]. Metals, 2022, 12(7):1203. [18] NGUYEN T T, PARK J, KIM W S, et al. Effect of low partial hydrogen in a mixture with methane on the mechanical properties of X70 pipeline steel [J]. International Journal of Hydrogen Energy, 2020, 45(3):2368-2381. [19] MENG B, GU C H, ZHANG L, et al. Hydrogen effects on X80 pipeline steel in high-pressure natural gas/hydrogen mixtures [J]. International Journal of Hydrogen Energy, 2017, 42(11):7404-7412. [20] ZHANG S, AN T, ZHENG S Q, et al. The effects of double notches on the mechanical properties of a high-strength pipeline steel under hydrogen atmosphere [J]. International Journal of Hydrogen Energy, 2020, 45(43):23134-23141. [21] NGUYEN T T, HEO H M, PARK J, et al. Fracture properties and fatigue life assessment of API X70 pipeline steel under the effect of an environment containing hydrogen [J]. Journal of Mechanical Science and Technology, 2021, 35(4):1445-1455. [22] AN T, PENG H T, BAI P P, et al. Influence of hydrogen pressure on fatigue properties of X80 pipeline steel [J]. International Journal of Hydrogen Energy, 2017, 42(23):15669-15678. [23] AN T, ZHANG S, FENG M, et al. Synergistic action of hydrogen gas and weld defects on fracture toughness of X80 pipeline steel [J]. International Journal of Fatigue, 2019, 120:23-32. [24] ZHANG S, LI J, AN T, et al. Investigating the influence mechanism of hydrogen partial pressure on fracture toughness and fatigue life by in situ hydrogen permeation [J]. International Journal of Hydrogen Energy, 2021, 46(39):20621-20629. [25] ZHUO J X, ZHANG C, ZHANG S, et al. Influence of hydrogen environment on fatigue fracture morphology of X80 pipeline steel [J]. Journal of Materials Research and Technology, 2023, 22:1039-1047. [26] NOVAK P, YUAN R, SOMERDAY B P, et al. A statistical, physical-based, micro-mechanical model of hydrogen-induced intergranular fracture in steel [J]. Journal of the Mechanics and Physics of Solids, 2010, 58(2):206-226. [27] WANG D, LU X, DENG Y, et al. Effect of hydrogen on nanomechanical properties in Fe-22Mn-0.6C TWIP steel revealed by in situ electrochemical nanoindentation [J]. Acta Materialia, 2019, 166:618-629. [28] CHEN Y S, LU H Z, LIANG J T, et al. Observation of hydrogen trapping at dislocations, grain boundaries, and precipitates [J]. Science, 2020, 367(6474):171-175. [29] GONG P, NUTTER J, RIVERA-DIAZ-DEL-CASTILLO P E J, et al. Hydrogen embrittlement through the formation of low-energy dislocation nanostructures in nanoprecipitation-strengthened steels [J]. Science Advances, 2020, 6(46):eabb6152. [30] AN T, ZHENG S Q, PENG H T, et al. Synergistic action of hydrogen and stress concentration on the fatigue properties of X80 pipeline steel [J]. Materials Science and Engineering: A, 2017, 700:321-330. [31] NEERAJ T, SRINIVASAN R, LI J. Hydrogen embrittlement of ferritic steels: observations on deformation microstructure, nanoscale dimples and failure by nanovoiding [J]. Acta Materialia, 2012, 60(13/14):5160-5171. [32] DWIVEDI S K, VISHWAKARMA M. Hydrogen embrittlement in different materials: a review [J]. International Journal of Hydrogen Energy, 2018, 43(46):21603-21616. [33] LYNCH S. Hydrogen embrittlement phenomena and mechanisms [J]. Corrosion Reviews. 2012, 30:3-4. [34] ROBERTSON I M, SOFRONIS P, NAGAO A, et al. Hydrogen embrittlement Understood [J]. Metallurgical and Materials Transactions A. 2015, 46(6):2323-2341. [35] 安腾氢气环境X80管线钢疲劳损伤行为研究北京中国石油大学(北京)2018安腾. 氢气环境X80管线钢疲劳损伤行为研究 [D]. 北京: 中国石油大学(北京), 2018. AN TStudy on fatigue damage behavior of X80 pipeline steel in hydrogen environmentBeijingChina University of Petroleum (Beijing)2018AN T. Study on fatigue damage behavior of X80 pipeline steel in hydrogen environment [D]. Beijing: China University of Petroleum (Beijing), 2018.

[36] MUSTAPHA A, CHARLES E A, HARDIE D. Evaluation of environment-assisted cracking susceptibility of a grade X100 pipeline steel [J]. Corrosion Science. 2012, 54:5-9. [37] NANNINGA N E, LEVY Y S, DREXLER E S, et al. Comparison of hydrogen embrittlement in three pipeline steels in high pressure gaseous hydrogen environments [J]. Corrosion Science. 2012, 59:1-9. [38] 李玉星, 张睿, 刘翠伟, 等. 掺氢天然气管道典型管线钢氢脆行为 [J]. 油气储运. 2022, 41(6):732-742. LI Y X, ZHANG R, LIU C W, et al. Hydrogen embrittlement behavior of typical hydrogen-blended natural gas pipeline steel [J]. Oil & Gas Storage and Transportation, 2022, 41(6):732-742.

[39] 刘方, 杨宏伟, 邓付洁. 掺氢天然气输送用X65管线钢的氢脆行为 [J]. 油气储运. 2023:1-8. LIU F, YANG H W, DENG F J. Research on hydrogen embrittlement behavior of X52 pipeline steel for hydrogen doped natural gas transportation [J]. Petroleum and New Energy, 2024(3):30-35,59.

[40] NGUYEN T T, BAE K, JAEYEONG P, et al. Damage associated with interactions between microstructural characteristics and hydrogen/methane gas mixtures of pipeline steels [J]. International Journal of Hydrogen Energy. 2022, 47(73):31499-31520. [41] BRIOTTET L, BATISSE R, de DINECHIN G, et al. Recommendations on X80 steel for the design of hydrogen gas transmission pipelines [J]. International Journal of Hydrogen Energy. 2012, 37(11):9423-9430. [42] AMARO R L, DREXLER E S, SLIFKA A J. Fatigue crack growth modeling of pipeline steels in high pressure gaseous hydrogen [J]. International Journal of Fatigue. 2014, 62:249-257. [43] 关鸿鹏, 林振娴, 李瑜仙, 等. X70管线钢及焊缝在模拟煤制气含氢环境下的氢脆敏感性 [J]. 工程科学学报. 2017, 39(04):535-541. GUAN H P, LIN Z X, LI Y X, et al. Hydrogen embrittlement susceptibility of the X70 pipeline steel substrate and weld in simulated coal gas containing hydrogen environment [J]. Chinese Journal of Engineering, 2017, 39(4):535-541.

[44] 李天雷, 冯敏, 梁爽, 等. X70管线钢管环焊接头氢脆敏感性研究 [J]. 焊管. 2023, 46(5):16-22. LI T L, FENG M, LIANG S, et al. Study on hydrogen embrittlement susceptibility of X70 pipeline steel pipe girth welded joints [J]. Welded Pipe and Tube, 2023, 46(5):16-22.

[45] ALVARO A, OLDEN V, MACADRE A, et al. Hydrogen embrittlement susceptibility of a weld simulated X70 heat affected zone under H2 pressure [J]. Materials Science and Engineering: A. 2014, 597:29-36. [46] SHANG J, ZHENG J, HUA Z, et al. Effects of stress concentration on the mechanical properties of X70 in high-pressure hydrogen-containing gas mixtures [J]. International Journal of Hydrogen Energy. 2020, 45(52):28204-28215. [47] WANG C, ZHANG J, LIU C, et al. Study on hydrogen embrittlement susceptibility of X80 steel through in-situ gaseous hydrogen permeation and slow strain rate tensile tests [J]. International Journal of Hydrogen Energy. 2023, 48(1):243-256. [48] ZHOU D, LI T, HUANG D, et al. The experiment study to assess the impact of hydrogen blended natural gas on the tensile properties and damage mechanism of X80 pipeline steel [J]. International Journal of Hydrogen Energy. 2021, 46(10):7402-7414. [49] BRIOTTET L, MORO I, LEMOINE P. Quantifying the hydrogen embrittlement of pipeline steels for safety considerations [J]. International Journal of Hydrogen Energy. 2012, 37(22):17616-17623. [50] MORO I, BRIOTTET L, LEMOINE P, et al. Hydrogen embrittlement susceptibility of a high strength steel X80 [J]. Materials Science and Engineering: A, 2010, 527(27/28):7252-7260. [51] RONEVICH J A, SONG E J, SOMERDAY B P, et al. Hydrogen-assisted fracture resistance of pipeline welds in gaseous hydrogen [J]. International Journal of Hydrogen Energy, 2021, 46(10):7601-7614. [52] SOMERDAY B P, SOFRONIS P, NIBUR K A, et al. Elucidating the variables affecting accelerated fatigue crack growth of steels in hydrogen gas with low oxygen concentrations [J]. Acta Materialia. 2013, 61(16):6153-6170. [53] SLIFKA A J, DREXLER E S, NANNINGA N E, et al. Fatigue crack growth of two pipeline steels in a pressurized hydrogen environment [J]. Corrosion Science. 2014, 78:313-321. [54] 史昊, 邢云颖, 王修云, 等. 煤制合成天然气管道材料适用性评价方法 [J]. 腐蚀与防护. 2019, 40(1):48-51,65. SHI H, XING Y Y, WANG X Y, et al. Applicability evaluation method of coal synthetic natural gas pipeline material [J]. Corrosion & Protection, 2019, 40(1):48-51,65.

[55] RONEVICH J A, SOMERDAY B P, FENG Z. Hydrogen accelerated fatigue crack growth of friction stir welded X52 steel pipe [J]. International Journal of Hydrogen Energy. 2017, 42(7):4259-4268. [56] RONEVICH J A, SONG E J, FENG Z, et al. Fatigue crack growth rates in high pressure hydrogen gas for multiple X100 pipeline welds accounting for crack location and residual stress [J]. Engineering Fracture Mechanics. 2020, 228:106846. [57] DREXLER E S, SLIFKA A J, AMARO R L, et al. Fatigue testing of pipeline welds and heat-affected zones in pressurized hydrogen gas [J]. Journal of Research of the National Institute of Standards and Technology. 2019, 124. [58] SHI X, YAN W, WANG W, et al. HIC and SSC behavior of high-strength pipeline steels [J]. Acta Metallurgica Sinica (English Letters). 2015, 28(7):799-808. [59] MARCHI C S S B PTechnical reference on hydrogen compatibility of materials: plain carbon ferritic steels: C-Mn alloys (code 1100)Livermore CaliforniaSandia National Laboratories2010MARCHI C S S B P. Technical reference on hydrogen compatibility of materials: plain carbon ferritic steels: C-Mn alloys (code 1100) [R]. Livermore California: Sandia National Laboratories, 2010. [60] KOMODA R, KUBOTA M, STAYKOV A, et al. Inhibitory effect of oxygen on hydrogen-induced fracture of A333 pipe steel [J]. Fatigue & Fracture of Engineering Materials & Structures. 2018, 42(6):1387-1401. [61] MICHLER T, BOITSOV I E, MALKOV I L, et al. Assessing the effect of low oxygen concentrations in gaseous hydrogen embrittlement of DIN 1.4301 and 1.1200 steels at high gas pressures [J]. Corrosion Science. 2012, 65:169-177. [62] CHATZIDOUROS E V, PAPAZOGLOU V J, TSIOURVA T E, et al. Hydrogen effect on fracture toughness of pipeline steel welds, with in situ hydrogen charging [J]. International Journal of Hydrogen Energy. 2011, 36(19):12626-12643. [63] ZHOU C, YE B, SONG Y, et al. Effects of internal hydrogen and surface-absorbed hydrogen on the hydrogen embrittlement of X80 pipeline steel [J]. International Journal of Hydrogen Energy. 2019, 44(40):22547-22558. [64] 封辉, 池强, 吉玲康, 等. 管线钢氢脆研究现状及进展 [J]. 腐蚀科学与防护技术. 2017, 29(03):318-322. FENG H, CHI Q, JI L K, et al. Research and development of hydrogen embrittlement of pipeline steel [J]. Corrosion Science and Protection Technology, 2017, 29(3):318-322.

[65] XU X, ZHANG R, WANG C, et al. Experimental study on the temperature dependence of gaseous hydrogen permeation and hydrogen embrittlement susceptibility of X52 pipeline steel [J]. Engineering Failure Analysis. 2024, 155:107746. [66] XING X, CHENG R, CUI G, et al. Quantification of the temperature threshold of hydrogen embrittlement in X90 pipeline steel [J]. Materials Science and Engineering: A. 2021, 800:140118. [67] SHI K, XIAO S, RUAN Q, et al. Hydrogen permeation behavior and mechanism of multi-layered graphene coatings and mitigation of hydrogen embrittlement of pipe steel [J]. Applied Surface Science. 2022, 573:151529. [68] AN T, LI S, QU J, et al. Effects of shot peening on tensile properties and fatigue behavior of X80 pipeline steel in hydrogen environment [J]. International Journal of Fatigue. 2019, 129:105235. [69] DMYTRAKH I M, LESHCHAK R L, SYROTYUK A M, et al. Effect of hydrogen concentration on fatigue crack growth behaviour in pipeline steel [J]. International Journal of Hydrogen Energy. 2017, 42(9):6401-6408. [70] HOMMA T, ANATA S, ONUKI S, et al. Crack initiation and propagation behavior of hydrogen-induced quasi-cleavage fracture in X80 pipeline steel with stress concentration [J]. Tetsu-to-Hagane. 2020, 106(9):651-661. [71] NGUYEN T T, HEO H M, PARK J, et al. Stress concentration affecting hydrogen-assisted crack in API X70 pipeline base and weld steel under hydrogen/natural gas mixture [J]. Engineering Failure Analysis. 2021, 122:105242. [72] 邹才能. 新能源新产业新动能新模式 [J]. 石油科技论坛, 2020, 39(3):前插1-前插2. ZOU C N. New energy, new industry, new kinetic energy and new model [J]. Petroleum Science and Technology Forum, 2020, 39(3):前插1-前插2.

-

期刊类型引用(1)

1. 王磊,赵红波,刘斌,毕宗岳,张锦刚,张敏,马宏伟. 电化学充氢对不同焊接工艺下管线钢焊接接头氢脆敏感性研究. 焊管. 2025(05): 18-26 .  百度学术

百度学术

其他类型引用(0)

下载:

下载: